So funny that we dubbed the new Chiron a God… when along comes this 2017 Regera in production form. Shouting another mighty name… the King!

Swear to…. oh nevermind.

(see below for the quote from Auto Motor and Sport).

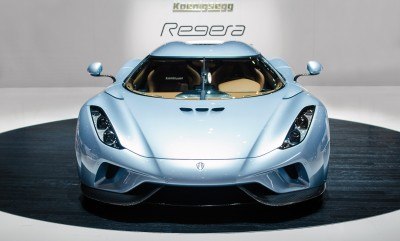

The 2017 Regera has been made real from concept form last year, with over 3000 changes and a seriously advanced new design, tech package and hyperspeed PHEV drivetrain.

Putting out some SERIOUS wattage, by the way.

Or actually, kilo-watts! 525kW is the output of a worlds-first 800-volt electric drive system.

All this in addition to the monstrous V8, of course. Power is claimed at 1500-plus, with the sprint times absolutely surreal for a rear-drive hypercar. 2.8s to 100-kph, 6.6s 0-200-kph, 10.9s to 300-kph, or 186-mph!

Obscene! Total weight is also strikingly low, at a dry total of just 3244-lbs.

First deliveries are set for later in 2016…. just in time for Koenigsegg in Ängelholm to face off its rivals from Molsheim!?

2017 Koenigsegg REGERA – Production-Spec model in red

Koenigsegg Automotive AB are proud to present the following vehicles at the 2016 Geneva Motor Show:

- Production Spec Koenigsegg Regera

- Koenigsegg Agera ‘Final’

- Koenigsegg Agera RS

Koenigsegg Regera – Production Specification

Koenigsegg Automotive AB is proud to unveil the Koenigsegg Regera in production specification, signaling a new era in Megacar performance.

The Koenigsegg Regera was introduced in concept form at the 2015 Geneva Auto Show to a rousing reception. Numerous customer orders were received during the show and have continued at a steady pace as the wider Koenigsegg family learns about the all-new philosophy and technology behind the Regera.

The 12 months since Geneva 2015 has seen the Regera evolve from a promising concept into an astounding reality, with the car put through an intense period of development, testing and homologation for worldwide sale.

So extensive was this development period, in fact, that over 3,000 changes were made to the concept vehicle. The weight savings achieved resulted in a curb weight – complete with all water, oils and fuel – of just 1590kgs. Dry weight is 1470kgs.

Koenigsegg Direct Drive

The patent-pending Koenigsegg Direct Drive system was the biggest challenge in the Regera development process, but it has also provided the biggest rewards. This is brand new technology that eliminates the weight, complexity and mechanical losses that come with a traditional gearbox. The end result is seamless, effortless driving that features blistering acceleration unlike any other car.

A number of enhancements have been made to elements of the Direct Drive system throughout the development process, making the Regera even more revolutionary than first envisioned.

Koenigsegg has developed a clutch-slip mechanism that uses the hydraulic coupling to convert torque at medium/high speeds during fast acceleration. This allows the combustion engine to gain revs and power, thereby giving the sensation of a traditional downshift with the associated aural enjoyment, even without the traditional gearbox.

Shift paddles remain on either side of the steering wheel. The left paddle is used to enhance the regenerative braking effect in recharging the battery pack. The right paddle is used to activate the hydraulic coupling’s ‘downshift’ operation.

Extreme Battery Technology

Koenigsegg worked extremely hard to find the best performing and safest battery pack possible for the Regera. This research and testing has resulted in an 800 volt, 4.5kWh battery pack, making the Regera the world’s first 800V production car.

This extreme battery technology will now provide an amazing 525kW of discharge and up to 200kW of recharge.

The Koenigsegg Regera battery pack also boasts the highest cooling capacity of any battery in automotive use today. All electric vehicle manufacturers use coolant piped around the battery pack to draw heat from the batteries. There is always an area that traditional cooling pipes cannot reach, however. The Regera battery pack is housed in a sealed unit featuring optimized local coolant flooding across all critical heat-sensitive elements. Every critical surface within and around the battery stack is cooled as efficiently as possible.

The pièce de résistance is the battery pack’s weight. The battery pack used in the production Regera uses Formula 1 grade, hand built cells that not only provide improved performance and regenerative capability, but also save 25kg in weight compared to the battery in the concept vehicle. This new, Formula 1 grade battery pack now weighs a mere 90kg whilst providing enough power to help the Regera to accelerate to 300km/h in just 10.9 seconds.

A New Breed of Performance

The Koenigsegg Regera represents a new and unprecedented era of high performance motoring. This is thanks to the car’s massive 1500+ hp output, 2000+ Nm of torque and the Koenigsegg Direct Drive system used to put this power to the ground.

The Regera will reach 0-100 km/h in 2.8 seconds, 0-200 in just 6.6 seconds and 0-300 in a blistering 10.9 seconds. Koenigsegg estimate a 0-400 km/h time of 20 seconds and acceleration from 150 to 250km/h in just 3.9 seconds.

Despite such scintillating performance, Regera owners can also expect the most refined driving experience yet from a Koenigsegg car. New active engine mounts provide a sense of isolation and peace within the cabin at lower speeds, but firm up for a more active driving experience when required – a true Jekyll and Hyde proposition.

Auto Motor and Sport was the first, and the only magazine so far, to test drive the Regera prototype. This is what they had to say:

“Power has never, and I say never, been this brutal, efficient and easy to use. This is a game changer of biblical proportions……. THE KING!”

New Solutions from In-house Research

Although small, Koenigsegg has always been a remarkably self-sufficient and extremely vertically integrated vehicle producer focused on in-house solutions developed at the Koenigsegg facility in Ängelholm.

Components that all other manufacturers buy in such as, wheels, brake calipers, engine and transmission management systems are all designed, engineered and build in-house Koenigsegg. Similarly, the entire mechanical drivetrain from combustion engine to DirectDrive unit, is all created by Koenigsegg. The benefit of working this way is that critical systems get seamlessly integrated and continuously optimized over time, to levels otherwise unobtainable.

A shining example of the above is that the hydraulic coupling used in the Regera was is designed and developed completely in-house. The “HydraCoup” can provide slip with very limited heat build-up while maximizing torque conversion and lock-up functionality. It is light, strong and efficient, weighing no more than the lightweight dry clutch in the Agera. It also looks like a piece of artisan jewellery. The only way to reach the goals of low weight and maximum torque transfer was to do it in-house as nothing available in the market place came close to the required specification.

These solutions, along with a new external high voltage DC charger, smaller 800V AC compressor and a new super-compact bespoke and lightweight 800V DC/DC converter all mean that the production version of the Regera is significantly lighter than the prototype it is based on, which is highly unusual when progressing to production-ready materials.

Comfort, Convenience and Technology

The interior of the Regera features optimum comfort and functionality.

Koenigsegg’s unique ‘Autoskin’ function allows the driver to open the doors and front and rear hoods remotely using a lightweight hydraulic system. Buttons for operation of ‘Autoskin’ are available both on the driver’s remote control key and via the centre console inside the car.

Additional compartments have been fitted in front of the driver and passenger, where personal items such as phones, wallets, etc can be stored.

The wing mirrors now fold automatically when the doors open to further increase the practicality of the dihedral synchrohelix door actuation system. Furthermore, as the Autoskin function allows for the doors to open automatically, we have fitted the doors and wing mirrors with proximity sensors in order to safeguard against the doors striking nearby objects (curb, low roof, etc) while opening or closing.

To complement the rear camera and the side door cameras, there is also the option of a forward facing camera that works together with the other cameras in the car to enable a birds-eye view of the of the car while parking or maneuvering in confined areas.

Apple CarPlay is standard equipment in the Regera and with Wi-Fi functionality, there is no longer any need to connect a phone via USB. Inductive charging ensures that an owner’s phone remains ready for use once a journey has ended.

The seats now feature heating and electrical adjustment with memory function. All in all the Regera is truly a fusion of luxury, comfort and race car performance. Compromise is avoided at all cost. A sense of theatre, mega-performance, luxury and light weight are all in equal focus like never before.

Conclusion

Koenigsegg’s vision has always been to find the best possible solution to a given challenge. Our enduring goal is maximum performance; the pursuit of automotive perfection. The Regera is the latest embodiment of that vision.

It is an extraordinary leap into the future of extreme high performance motoring. Whether it be a contest of performance or a contest of ideas, the Regera concedes nothing. It is a gracious grand tourer, a technical tour-de-force and of course, we still maintain that the only way to be faster around a racetrack than the Regera is to drive another Koenigsegg.

It is yet another car from Ängelholm to earn the Megacar moniker.

All new technologies developed by Koenigsegg have integrated seamlessly into the Regera to enhance the total experience and give our customers the best luxury performance car available for sale in the world today.

We are very much looking forward to sharing the Regera experience with the world over the coming months as we commence the build of customer cars in the immediate future and deliveries at the end of 2016.

——

Tom Burkart is the founder and managing editor of Car-Revs-Daily.com, an innovative and rapidly-expanding automotive news magazine.

He holds a Journalism JBA degree from the University of Wisconsin – Madison. Tom currently resides in Charleston, South Carolina with his two amazing dogs, Drake and Tank.

Mr. Burkart is available for all questions and concerns by email Tom(at)car-revs-daily.com.